Hybrid type sintering machine (continuous type)

New Hybrid Sintering

Compact and Continuous process available!

SiC RF Induction Heating+Pulsed power+Servo press

HMS-0050M

Description

In combination with high-frequency heating and plasma discharge heating, it can do uniform sintering by a servo press control of the punch, after being heated in a few minutes up to a high temperature range. A shorter sintering time compared to the hot press, further maximizing the efficiency as it is equipped with a continuous sintering feature of our own development.The machine is also suitable for research purposes and mass production. (Patent number: 6678434)

Feature

- The speed of sintering process is enhanced by a hybrid heating system in combination with a pulse current and HF induction

- A combination of high-frequency induction heating allows for lower temperature and a shorter time period procedure without the need for bounding materials

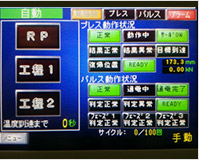

- Possible to control the precise pressure and pressing position by the high-performance servo press

- The monitoring of the torque management and work resistance value of the press allows for delicate adjustment of sintered density

- Heating recipe and atmosphere in conjunction with the press control by the program

- Continuous sintering features of our own development

Technology

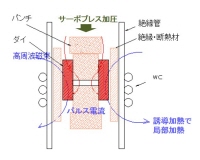

Hybrid heating & precise press control

RF Induction heating, Electric plasma heating make quick temperature increase to high temperature zone. Servo press provides precise sintering control.

Originally designed Continuous Sintering Process

Continuous sintering process helps ensure high productivity.

8 stations(8 cartridges) are provided in the continuous sintering system. 8 different types of sintering processes are available to be set individually which will shorten test time in laboratory.

Sic power module help RF Induction heating to save cost of energy consumption.

-

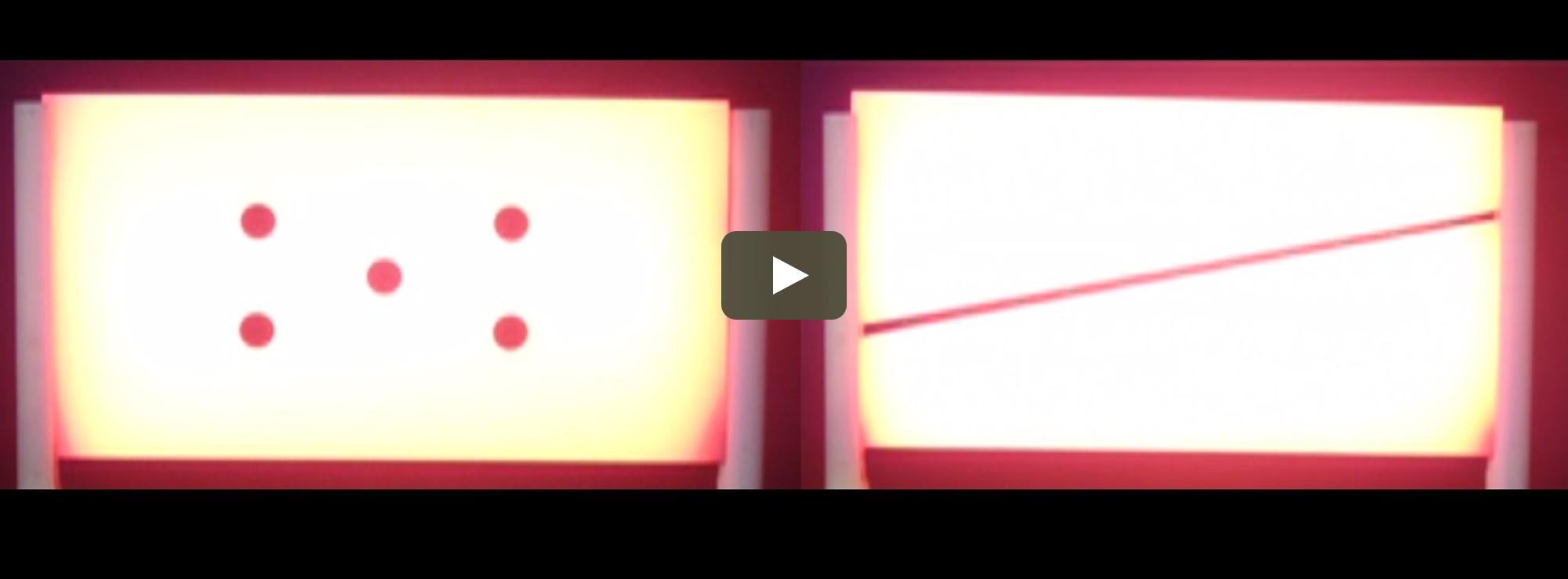

Principle of hybrid sintering

-

Easy operation by touch panel

-

Precise control by servo press

Application

|

Heating method |

High-frequency induction heating + pulse current heating |

|---|---|

| Heating temperature | 2000℃ |

| Heating rate | 400℃/min |

| Chamber | Heating chamber + continuous chamber |

| Atmosphere | Inert gas atmosphere after vacuum |

| Press method | Servo press 50kN |

| Temperature measurement | Thermocouple or 2 color pyrometer |

| Optional |

Ultimate vacuum 1×10-4Pa, Hydraulic press (Pressure control) |

| Industrials |